For a product such as a pipe, stainless steel is the most popular material due to its unique properties. Stainless Steel Pipe is used in a wide variety of industries and is produced in various types. To determine whether a pipe suits you. You need to know its profile, thickness, grade of steel, and the technology by which it was made.

When deciding on a purchase, keep in mind that the cost of a stainless steel pipe will consist of the following factors:

- steel grade;

- geometric parameters - section, thickness, length;

- manufacturing method;

The presence of insulation.

The choice of stainless steel pipe parameters will depend on the mechanical and chemical loads and the duration of their exposure.

Features, characteristics, application, welding method

Section geometry is the first thing to decide when choosing a stainless steel pipe. For pipelines, chimneys, fences, decorative structures, a round stainless pipe is used. For construction purposes, a stainless profile pipe is usually selected.

Round pipe

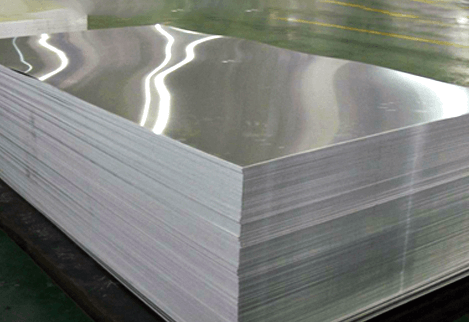

A stainless round pipe can be made of rolled sheet stainless steel by welding the seam, as well as using seamless technology.

Electric welded

Electric-welded stainless steel pipes by the production method can be divided into spiral-seam and longitudinal-seam. Large diameter electric welded pipes are often supplied in polyethylene insulation. The Aluminium Supplier In Singapore also supplies the various pipes for industrial purposes.

Seamless

Seamless stainless steel pipe compares favorably with an electric welded pipe in that it has the same strength along the entire length. It can be made by pulling a hot workpiece or puncturing a cold one. The first method is usually used for the manufacture of pipes of smaller diameter. Seamless pipe is most often used in the petrochemical industries, which places high demands on the reliability of pipelines.

Profile pipe

Profile pipes are called oval, rectangular or square pipes. Their resistance to deformation, corrosion, and temperature extremes is widely in demand in construction. The tightness of such pipes is not of great importance since they are not used to move liquids and gases. Thin-walled stainless profile pipe is used in construction to create frames for lightweight structures. More expensive thick-walled profile pipes can withstand heavy loads.

Rectangular

The corrosion-proof rectangular pipe is made similarly to a square one, according to Rectangular shaped pipes by section size in mm.

Stainless Steel Singapore products have a wider application than a square one, and in some cases is cheaper.

From where should you buy stainless steel pipes?

The first company that came across the query, “buy a stainless steel pipe,” is not the best solution. Although it is becoming more civilized year by year, the stainless steel market is still full of unscrupulous suppliers.

Choose market leaders who work directly with steel companies and provide product certificates. Such companies have well-established customer service, and deliveries are made on time.

If you need a stainless steel pipe, you can buy it from Stainless Steel Supplier Singapore, which offers the widest assortment and favorable purchase conditions. At the company's warehouse in Moscow, not only the sale of stainless pipes is carried out, but also all types of metal processing.