The benefits of using a corrosion-resistant metal in tube construction should be obvious at all times. Therefore, stainless steel is a common choice for piping. It's possible to become confused between pipes and tubes due to the wide variety of shapes and sizes available for each. Because of this, we often classify pipelines based on their functions.

Grade 304 stainless steel is a popular pipe alloy. A better chemical resistance is another benefit of 304, making it a good choice for items that will be subjected to high levels of water contact, as is often the case in industrial settings. India is home to some of the world's finest h beam sizes.

However, 304 isn't good at handling temperatures beyond 800 degrees Fahrenheit since it becomes vulnerable to carbide precipitation at such levels. 304L stainless steel is recommended for these uses. Maintaining contact with aluminium profile Singapore is a simple process.

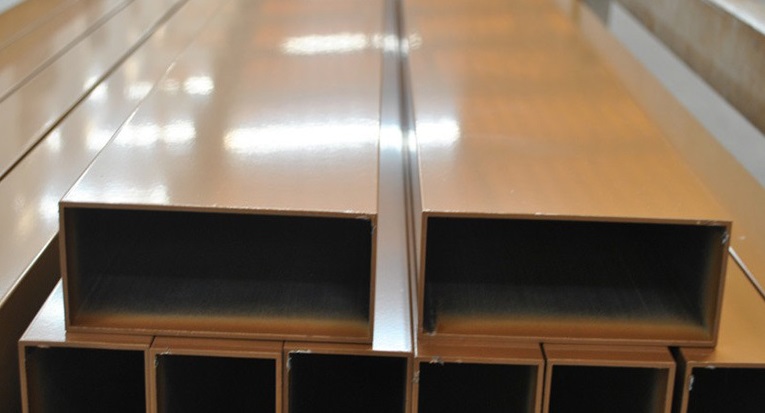

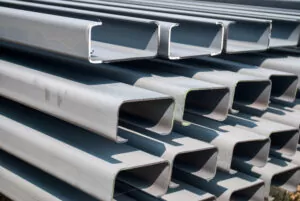

One common use for pipes is for stainless steel stress pipe. All chromium or a chromium-nickel alloy makes up this specific stainless steel kind. These pipes are often made from ferritic or austenitic metals. Applications include, but are not limited to, the use of seamless tube, welded tube, electric fusion welded tube, and large diameter welded tube. This tube can withstand high pressure and temperatures and is resistant to corrosion. You can easily rely on gi sheet at any point of time.

Another common use for stainless steel tubing is in sanitary plumbing. For instance, sanitation plays a crucial role in the production of food and beverages as well as medical equipment. Stainless steel's resistance to corrosion, cleanliness, and tarnishing make it a desirable material. The ASTMA270 alloy seems to be the metal of choice for plumbing fixtures. Manufacturers of galvanized steel pipe have consistently delivered high-quality products.

High-performance sectors like aerospace and engineering both benefit from the usage of stainless steel tubes. Aeroplanes need a high level of heat resistance, which is why alloys based on chromium and nickel are used. Strong, work-hardening, and weldable are other important qualities in aircraft tube made of stainless steel. Steel grating is indeed a simple process.

Stainless steel tube alloys 304, 304L, 316, and 316L are all available online. Construction is a common use for our stainless-steel tubes. The ductility allows for straightforward wall installation without the requirement for any kind of heat treatment. From what we've learned, steel pipes used for plumbing typically last for about 50 years. Distributors of steel beam can be found in a lot of places.

As time goes on and traditional tubes fall farther and further into usage, the quality of the materials used in pipelines is becoming an increasing concern. The two most crucial things to accomplish are have an understanding of the potential downsides, as well as an awareness of the available choices. For a variety of reasons, using tubes made of stainless steel is better in terms of both one's health and one's impact on the environment.