Steel plate refers to a flat sheet of steel that can be further processed into a variety of industrial goods. Thicker or thinner steel plates are available and can be cut to any size you require. Standard sizes are 48 inches by 96 inches and 96 inches by 120 inches, among others. Steel plate is a generic phrase. There are as wide varieties of steel plate as there are:

- Perforated Sheet

The Stainless Steel 304 perforated sheet comes from the manufacturing method of "perforation," which entails punching holes in the material to create a variety of slots. Always check with the perforated sheet manufacturer to find out what solutions they may offer. Depending on the type of holes punched in the perforated sheet, these products can be used for a variety of purposes, including providing ventilation, dissipating heat, and reducing noise. Due to their unique appearance, they are sometimes incorporated into decorative gadgets.

- Pipe Fitting

Various fluid control items, such as valves and pumps, must be joined together using pipe fitting singapore to construct pipelines. The most prevalent type of fittings is those used with fluid-carrying metal and plastic pipes. Different types of pipe fittings can join in architectural applications like railings and other decorative features, where a water-tight seal is unnecessary.

- Pipe Flanges

A flange is typically used for constructing pipes and has a disc-like shape. Daily, oil and gas are transported along 1,382,569 pipelines, as reported by the Pipeline and Hazardous Materials Safety Administration. The engineering of pipelines often involves the use of long weld necks and other forms of pipe flanges. Flanges are a crucial component of every pipeline system. They're used to make sure two pipes have a water-tight seal when joined together.

- Stainless Steel Fabrication

Stainless steel fabrication is the process of making structures out of stainless steel by actions such as cutting, bending, and assembling. Welding is the most common method for this task, though several others exist. stainless steel fabrication singapore is used in construction, the auto industry, and many other fields.

- Stainless Steel Pipe

Both resistance and the presence of chromium, which provides immunity to corrosion and other forms of damage, are shared traits of stainless steel pipe. The stainless steel pipe can withstand harsh chemicals like acids and alkalis. Grades of pipe with higher nickel concentrations, molybdenum, and chromium are less likely to corrode.

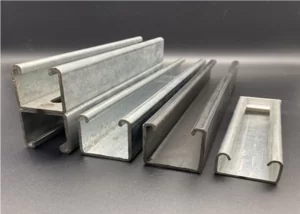

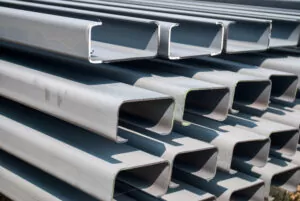

- Stainless Steel Plate

The stainless steel sheet metal is used to classify several iron-based alloys. Hence, it's a metal comprising two or more different elements. They have a chromium content of 10.5% or higher. stainless steel plate have increased durability and longevity thanks to the addition of chromium, which also improves the material's resistance to corrosion. A passive coating of chromium forms on stainless steel, acting as an insulator. This non-active coating will protect against rust foaming and corrosion.

Conclusion

Steel is a metal of great industrial value. It is available in a variety of amazing quality levels. Use its adaptability to come up with a wide range of items to meet a variety of purposes. As a result of its strength and durability, stainless steel can help you get your money's worth once again. Stainless steel products are a good investment because they will last long.