Stainless steel is one of the most versatile and valuable materials in the world, for a good reason. Not only is it healthy, but it also looks stylish and beautiful. Check out the best benefits of stainless steel and see if it is suitable for your next project:

If you're not sure which metal to choose for your next project, consider stainless steel. These are just some of the benefits of this metal.

- Power

One of the main reasons stainless steel is more sought after is resistance, held at both very high and very low temperatures.

- Cleaning

Stainless Steel Pipe is one of the most hygienic materials and is not compatible with the growth of bacteria and other pathogens. Even better, stainless steel is very easy to clean and maintain, requires a simple cotton swab with a universal cleaner and a quick polish along with the particles. Stainless steel requires less maintenance and is easy to clean, making it ideal for places where cleanliness is required, such as hospitals and kitchens.

- Aesthetics

One of the main reasons homeowners choose stainless steel for their homes is the metallic appearance. Fortunately, metals are not only beautiful; they are also very functional.

It is undeniable that stainless steel only looks good. After all, there is a reason why homes with stainless steel appliances are more sought after than homes without stainless steel appliances.

- Corrosion resistance

This metal is resistant to corrosion, rust, and scale. It also makes the metal ideal in all areas where extreme temperatures and pressures can be present. Steel Supplier Singapore is the biggest suppliers of stainless steel.

Chromium is added when making stainless steel. It then combines with oxygen in the air to form a film on the metal. This film heals as soon as it is damaged, allowing the metal to withstand corrosion and rust. The addition of other elements such as nickel, titanium, and molybdenum further improves the corrosion resistance of stainless steel.

- Recyclability

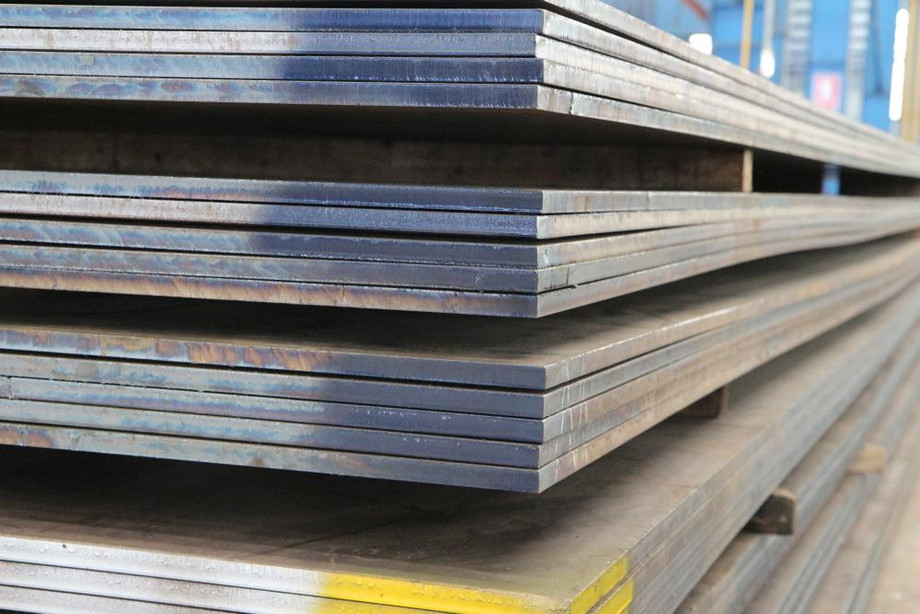

Stainless Steel Plate is a material that continues to yield. Once stainless steel has served its intended purpose, it can be recycled.

- Durability

Stainless steel is one of the most durable metals on the market because it is extremely durable and does not bend under light weight or heavyweight. It can withstand weight, high and low temperatures, and extreme weather conditions.

Ease of manufacture:

With state-of-the-art steelmaking technology, stainless steel can be welded, cut, machined, manufactured, and moulded as easily as traditional steel. It provides the long-term value created by the long life cycle, which often produces the cheapest material options.

Resistance to high and low temperatures:

Due to its fire and heat resistance, most grades are resistant to fouling and can maintain high resistance to maximum temperatures.

Aesthetic charm:

Stainless steel is available in many surface finishes. Easy to maintain and simple, it has a high quality, modern and attractive look. Stainless steel appliances can complement almost any kitchen, home, and design theme. Stainless Steel Singapore has best quality stainless steel.

Strength vs. weight benefits:

Due to the true grade work curing properties, high material strength can be obtained only by cold working, and high strength duplex grade can be obtained. This allows the material to be used thinner than traditional grades, often saving costs.