Introduction:

The material is forced through a die with a specific cross-sectional profile in aluminum extrusion. A heavy ram forces the metal through the die and emerges from the die's hole. When this occurs, it appears in the dice shape and is transported down a runout table.

When broken down into its core components, the process is easily understood. The force exerted is analogous to squeezing a bottle of toothpaste. When you press a tube of toothpaste, the paste comes out in the shape of the tube's opening. Opening a toothpaste line serves the same function as an extrusion die.

- Aluminum Extrusion:

Aluminium extrusion Singapore is a useful production method, but the final product can be affected by several variables. If you want your project to be a success, you should think about these things. The complexity and cost of extruding a given part depend on its shape. However, there are constraints on the variety of conditions that can be made using extrusion. For instance, solid forms are simpler and quicker to extrude than hollow ones. They'd be cheaper than similar products with more complex shapes since extruding those shapes is more difficult and expensive.

- Expanded metal mesh:

Expanded metal can be used instead of traditional metals like sheet metal or wire mesh. It's an excellent compromise, offering the advantages of fine wire mesh and sheet metal in a single product. It's a great alternative to traditional wire for use in bespoke baskets that require greater tensile strength. Expanded metal mesh baskets of highly resistant metal alloys like grade 316 stainless steel are extremely durable and adaptable. They're interesting to investigate because of the wide range of applications across all of Marlin Steel's target markets.

- Slotted angle bar:

Low carbon steel slotted angle bar, also known as slotted angle iron, has a cross-section in the shape of an L with two legs that might be equal or unequal and an angle of 90 degrees. Slotted angles' slot designs are optimized for the possible nut and bolt configurations, making using any combination of angles possible. Slotted angle bars provide a sturdy, quick-to-assemble angle framework that can be bolted together, making them ideal for uses that call for a custom-fitted building. Galvanizing or spray painting cold-rolled slotted angle bar increases their durability and shelf life.

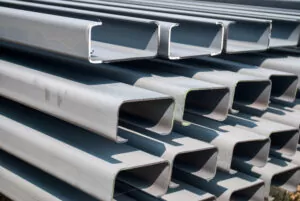

- Lip channel:

Lip channels, or C channels or C purlins, are "C" shaped steel profiles made from hot-rolled mild steel or galvanized "C" shaped steel with inner radius corners. lip channel, with their C-shaped form, are exceptionally sturdy and reliable under both horizontal and vertical loads. Lip channels and C purlins are simple to machine, cut, and weld because of their prefabricated shape. Lip channel, also known as C purlin, is used in various contexts, including but not limited to light and heavy manufacturing, construction, industrial maintenance, transportation, automotive, and agricultural implements.

- Unistrut:

The general-purpose profiles known as stainless steel unistrut or stainless steel unistrut channels are frequently employed as structural support in various business and manufacturing settings. Both solid and slotted channel variations of stainless steel unistrut Singapore are commercially available.