Introduction

When disassembly of a pipe junction is necessary, flanges are employed. These are typically installed in machinery, controls, and specialized applications. Breakout flanges are installed at regular intervals in pipes that require frequent servicing. The purlins support the roof deck.

The flanges, the gaskets, and the bolts all work together to form a flanged joint, yet they are all technically distinct parts. A leak-proof joint requires careful consideration in selecting and applying all these components.

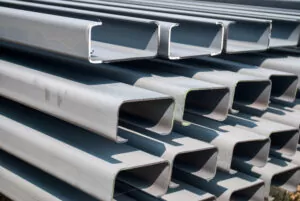

- Purlin:

Purlins are horizontal beams or bars used for roof support in architecture, structural engineering, and building. The rafters or the walls of a structure hold up the purlins. While they are commonly seen in metal structures, they can also be utilized to replace closely spaced rafters in wooden ones.

The term "roof deck" refers to the wooden panel, plyboard, or metal sheets that make up the roof's surface. If it's made of wood, it will have weatherproofing and insulation applied to it.

- Galvanized steel:

During production, steel or iron receives a protective zinc coating, known as galvanizing or galvanization. Hot-dip galvanizing is the most widely available and widely used of several galvanizing techniques.

Due to the zinc-iron coating's corrosion protection and the steel's increased durability, strength, and formability, galvanized steel is one of the most widely used steels. The zinc acts as a barrier against corrosion, and the coating's sacrifice makes for a durable, high-quality steel product that will last long.

How is Galvanized Steel Put to Use?

The use of galvanized metals is ubiquitous. Galvanized metals are used in the construction of numerous vehicles and bicycle frames. Galvanized steel water pipes are still in use in some areas. Galvanizing is another common treatment for cool rolled sheet metal. Galvanizing is a low-cost method of increasing the durability of metal. Therefore, it is now commonly used to treat nuts, bolts, tools, and wires.

Modern "steel frame" construction typically uses galvanized steel. Galvanized steel is also commonly used to construct verandas, balconies, stairs, ladders, walkways, and other elements. If the finished product is destined for outdoor use, galvanized metal is the material of choice.

Because of their durability and attractive appearance, stainless steel bars (also known as stainless steel rods, stainless rounds, or round stainless bars when formed into solid cylinders instead of square bars) are frequently used in construction and finishing.

- H beam sizes:

Three distinct pieces make up an H-beam. The beam consists of two parallel flanges at either end and a webbing made of metal that connects them. Compressive pressures are dissipated throughout these lengths, allowing the H-beam to support a heavy load without buckling. The resistance of the beam to bending forces is defined by its size. The beam's area moment of inertia is equal to the product of the beam's dimensions raised to the fourth power of the beam's length.

Conclusion:

Even though the final result of stainless steel can be modified in a wide variety of ways due to the wide variety of manufacturing methods that can be applied to it, most steel bar suppliers will normally split stainless products into five fundamental categories. During production, steel or iron receives a protective zinc coating, known as galvanizing or galvanization.