Steels are crucial materials for construction and manufacturing processes. Resistant and flexible, they are the primary materials used in constructing homes, offices, schools, hospitals, shopping centres, commercial buildings, and industrial structures. Here, we focus on some more versatile steel products and how they are best utilised.

The Multi-Purpose Steel Component

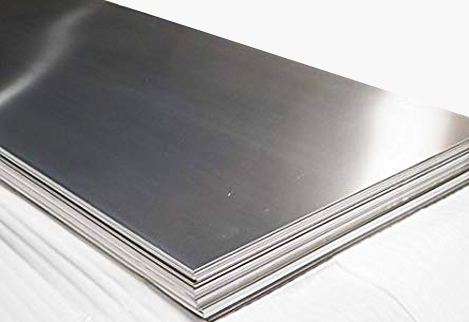

A flat bar is a simple and essential steel item. Basic steel items A Flat bar is one of the flat steel products or flat steel products. Flatter Steel Products' rectangular product form is commonly employed in structural, materials fabrication, and repair. Flat bars are easy for architects and engineers to cut, weld, and shape and must-have.

/img/eb/I8c/gsDo/0jOWdJYAzwP4e/4LGA1uqPUI/fmUKWhak5qKqXyry.jpg)

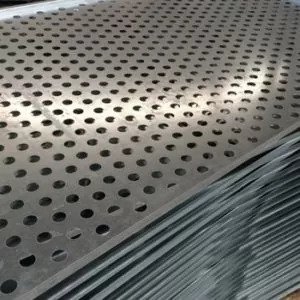

Protection Against Corrosion

Galvanised steel is widely characteristic in areas exposed to moisture. Being an alloy of steel, this steel product is coated with zinc to prevent rust and protect the structures. Due to its open structure, it is suitable for use in outdoor structures such as fences, roofs, and frames.

Uses of Steel Pipe That Has Been Galvanized

Because of the hard texture of the galvanised surface, the galvanized steel pipe remains viable for pipes and tunnels and other uses such as irrigation systems and even construction supports such as scaffolding. It does not rust due to its zinc coat which allows it to provide optimum performance in all weather types.

Lightweight and Durable

The gi sheet, or galvanised iron sheet, is light but very durable and can be used in the roofing industry, the cladding of buildings and industrial uses. It is pretty an effective material for intervening in weathering; hence, apart from its other properties, it easily fits the construction requirements without incurring much cost.

Structural S.H.P. is designed to match the requirements of every structure.

In large construction projects h beam sizes are useful because they offer enough options in terms of dimensions and load bearing ability. The concrete T-beams are very crucial in bridges, towers, and industrial construction they contribute to the strength of the building.

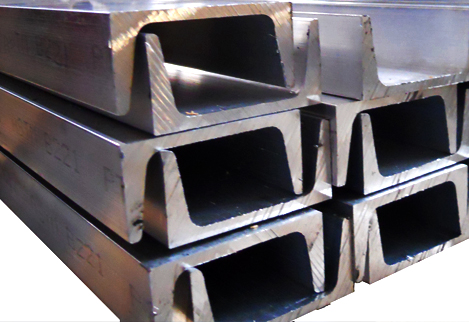

A multifunctional construction feature

The hollow section is a steel product which is characterized by a tubular section with a hollow center. It has great tensile strength, easy to fabricate, and it is rather light thus proving ideal for structural and mechanical uses. It is imperative for its utilization in the formation of enduring structures.

Standard used in the manufacture of Hollow Sections for custom measurements

projects vary in their requirements and clients can be assured that there are several hollow section size. These sections are tremendously informative about the versatility and rigidity of the little residential constructions to the huge industrial constructions.

/img/JN/9QJ/XNHY/mzFYBzb9XbXUa/9I2BnlOaUC/jGfDN39twEl0zlVo.jpg)

Essential for Heavy Loads

Primarily identified by the “I” shape, the i beam size is just as important when it comes to bearing high levels of structure and weights need for construction purposes. Where its usage is imperative, it is widely used in bridges, buildings and large frameworks construction.