Metal fabrication has been the process of creating anything out of iron or otherwise alloys by assembling or creating it. Professionals in the fabrication sector make almost anything specific out of metal, from specialized machine parts to further iron railings or otherwise gates.

Metal fabrication businesses are a part of our daily life. Fabricators make parts for the automobiles we drive, the houses we live in, as well as the everyday items we use.

Metal fabrication exhibitions are also essential for other 'higher end' items. They collaborate with architects, designers, artists, and entrepreneurs to make all kinds of wonderful things out of various metals. Consider a stunning stainless steel as well as glass staircase, a wrought-iron gate particularly in front of a house, or perhaps an aluminium bicycle frame. Iron fabricators create all of these amazing items! Perforated Metal is actually very good.

But who operates in the metal fabrication industry? The metal fabrication business employs a diverse range of individuals with a variety of job roles. To begin, consider welders as among the most important. Welders are persons who are extremely adept at joining metals together. Welders are often trained in a variety of welding techniques, including MIG welding, TIG welding, and ARC welding, to mention the top 3 most prevalent forms of welding. Skilled welders are among the most important personnel in just about any metal fabrication business, and they also earn some of the highest wages in the industry! Metal Perforated Sheet is used in many places.

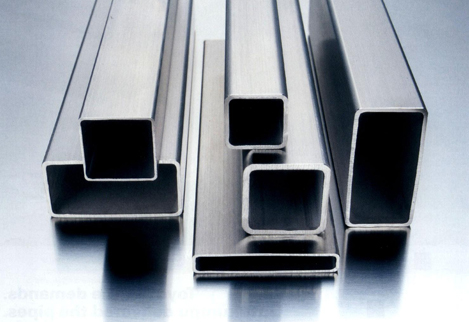

Other employees in every metal fabrication company include machinists, who actually help design as well as cut components - often with the aid of computers - as well as drafters, who use the computers for generating blueprints or perhaps even 3D models of the metal items before they're "made." Pipe Fitting Singapore is excellent.

Overall, metal fabrication is a big part of our own world, as well as metal fabrication firms play a massive part in the production of many of the items we use within a nation and throughout the world. Railings with a half-inch to one-inch bar are commonly utilized in both residential and business applications. When built of galvanized, painted, or otherwise stainless steel manufacturing, metal railings may be anticipated to last a century with next to no repair. You can always choose a good Stainless Steel Sheet for your work.

Strength, with little to no upkeep.

Lasting power. That is the allure of metal. That is why metal is used in so many goods. Metal fabricators specifically have the technology and know-how to transform base metals melted and created by steel mills into extremely useful items that may last a lifetime. Metal Plate is also used widely.

Metal fabrication as well as contract assembly have actually gone a long way, from particularly the smallest metal components for the electronics to huge fabrications such as aeroplane components as well as building frames. From the beginning of recorded history, with basic gold jewellery and painstakingly constructed machinery as well as weapons, to the current day, with greater complexity than anyone could have dreamed.