Metal fabrication seems to be the technique of bending, grinding, and constructing metal structures out of diverse metal bits and components. Sawing or otherwise shearing, laser cutting, or otherwise punching are the most common methods of cutting metal during manufacturing. Bending is accomplished using press brakes.

Press brakes utilize numerous dies to create the various sorts of bends needed by a specific project. The first step of metal manufacturing includes cutting as well as bending the particular metal. Welding is used to join metal components that have been cut as well as bent to the right sizes and forms. Angle Bar is actually very good.

Stamping is yet another method of metal production which is used for the larger quantities of the very same kind of part. The first stage is to design a stamp, or mould, that will be used in a particular stamping machine to actually stamp the pieces out of sheet metal. This method is used to produce a huge number of the same part. The mould is expensive to manufacture, but once the mould is obtained, multiple components may be produced fast, lowering the cost per each part. Stamping is commonly used for the vents, panels, hinges, and other components. C Channel is a great option.

While many other metals are utilized in metal production, steel is perhaps the most prevalent. Steel seems to be an iron-based alloy with various quantities of carbon added, ranging from 0.2 percent to 2.1 percent. You can also get a chequered Plate. Carbon appears to be the most commonly utilized ideal material because it is the least costly and provides desirable characteristics to the metal in proportion to the amount of carbon present which is added, like enhanced strength, malleability, as well as hardness. While the carbon steel is highly useful and flexible, it has one drawback: it corrodes as well as rusts. Flat Bar is an excellent product.

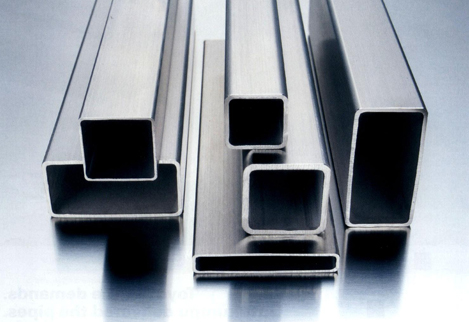

If corrosion resistance is somehow a problem for the work, the item should be actually coated or otherwise painted for the protection, or it could be manufactured of stainless steel. The alloys listed above are only a handful of the many metals that may be used. You should always try to have a Hollow Section.

Whenever preparing a metal fabrication work, one must be able to rely on their particular metal fabricator to propose and get the appropriate sort of metal for their actual needs.Metal Fabrication Singapore has been outstanding.

Metal Works Singapore seems to be a developing business. There are several fabricators to choose from, and it is critical that you choose the firm that would best meet your demands. A good fabricator would be able to select the best particular metal for your own project, design it for the manufacture, and also try to have a skilled manufacturing facility to give you with the best quality product and that too at the best possible price. You can find a good Metal Supplier Singapore.

No comments:

Post a Comment