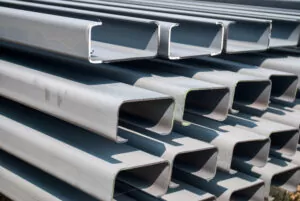

When you look at the design of the steel sections employed in construction, it helps to be aware of the significance of the design. The section's shape should provide the best support and for transmitting loads properly throughout the structure.

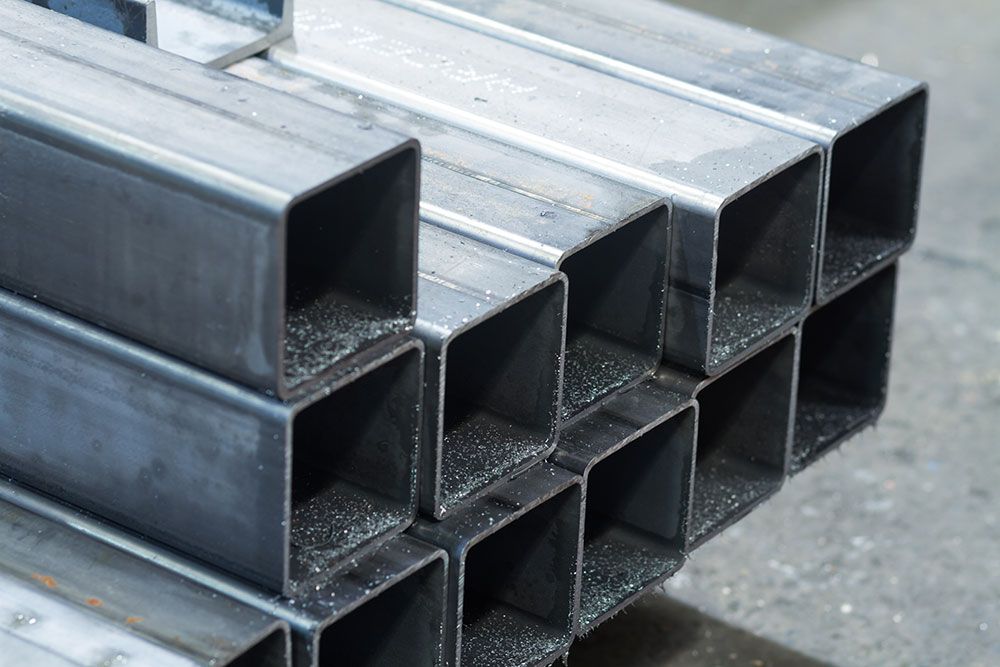

Hollow Structural Sections (HSS) are lengths of high-strength steel tubing, which is utilized as structural elements in building or general structures as well as various manufactured products. HSS is referred to as a closed-class and can be found in round, square, circular, and rectangular shapes. It is available in a wide range of sizes that can meet certain specifications.

HSS sections can be used for rotation and point loads and have a strong structural capacity against torsion and compression. The most commonly used applications of hollow section are for structural shafts and columns.

5 Benefits of Hollow Structural Sections

High Strength-to-Weight Ratio

HSS is not just the most affordable structural member It also has an extremely large range of gyration on both axes, which gives an excellent torsional strength and high compression efficiency with substantial weight savings. For greater axial capacity HSS segments can also be utilized as a cover for concrete columns.

Closed Section

Contrary to channel W and I sections that include open sides the hollow section size of the structure are enclosed sections that have all sides sealed off. This characteristic of HSS is a benefit in the resistance of torsional load. It is used in areas such as food processing facilities and clean environments, in which cleanliness is essential, HSS is the best option as it minimizes the surface that could accumulate dust and other debris.

Aesthetic Appeal

Due to their smooth edges as well as their rounded corners and closed sections HSS are frequently favored by architects, particularly when the exposed side of the structure adds to the design's appeal. HSS have been utilized in famous structures like The London Eye and Emirates Stadium. They also work well for use in everyday tasks like fencing, vehicle trailers and handrails.

Cost Saving

Because square and rectangular HSS comprise about two-thirds of that surface space of a open segment with the same capacity, this can be an economic benefit since there is less work to do as well as fewer painting supplies are needed, fireproofing using cementitious is reduced and a minimum amount of labour is required.

Sustainable and Adaptable

The hollow structural section is sturdy robust, durable, flexible reuseable and completely recyclable. HSS do not just create light and attractive structures, but they also are extremely adaptable and may easily be expanded in the future without fear of overburdening the foundations of the current structure.

No comments:

Post a Comment